- Feature

- Performance

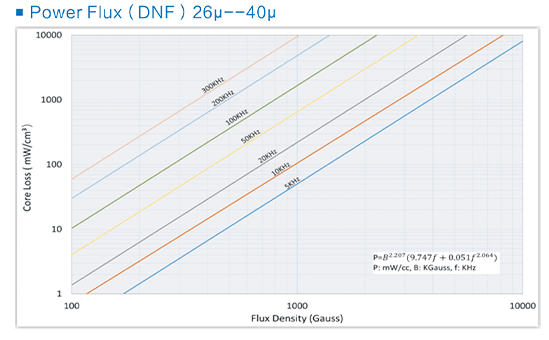

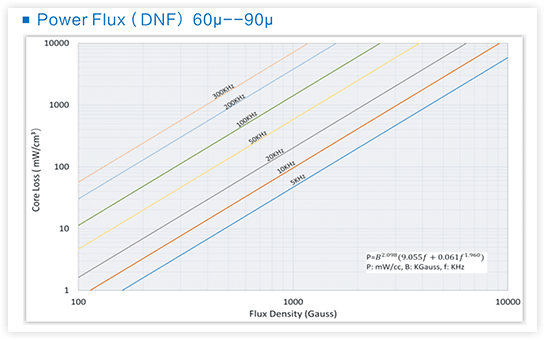

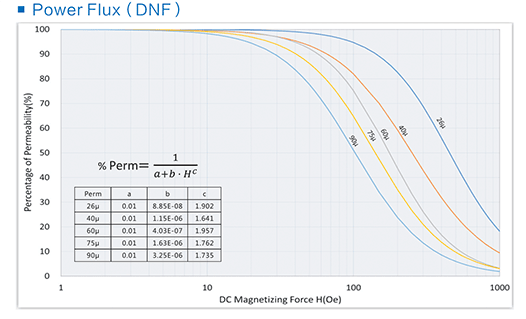

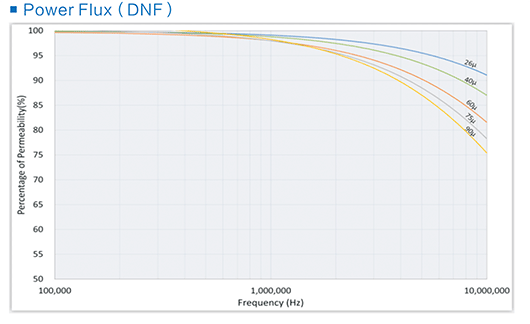

- Curve Comparison Chart

- Advantage

- Applications

- Video

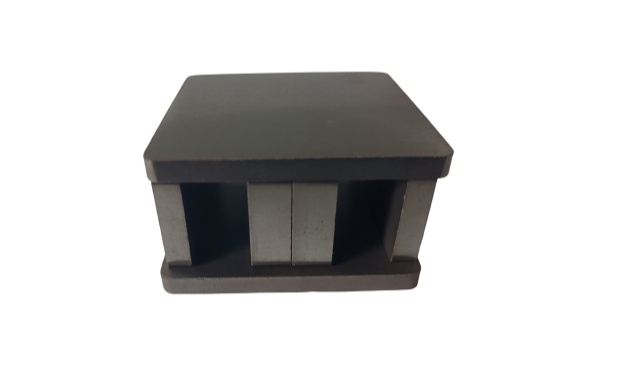

Feature

Feature Description

High Saturation Flux Density (16,000 Gauss);

Excellent DC-bias Characteristics;

Excellent Thermal Stability Without Aging Problem;

Stable quality and good conformity.

Performance

High magnetic permeability

Iron silicon has a high magnetic permeability, which means it has good responsiveness to magnetic fields. High magnetic permeability helps improve the efficiency of inductors and transformers, and reduces energy loss.

Low core loss

Iron silicon exhibits lower core loss, which means it can more effectively transmit and convert energy in AC circuits. Low core loss helps to improve equipment efficiency and energy-saving performance.

Good temperature stability

Iron silicon has good temperature stability and can maintain stable magnetic properties over a wide temperature range. This enables iron silicon to work reliably in environments with high temperatures or significant temperature changes.

Adjustable

The magnetic properties of iron silicon can be adjusted through appropriate heat treatment and alloy ratio. This allows Iron silicon to be customized according to specific application requirements to meet different magnetic field strength and frequency requirements.

High saturation magnetic induction intensity

Iron silicon has a high saturation magnetic induction intensity, which refers to the maximum magnetic induction intensity that a material can achieve under the action of a magnetic field. The high saturation magnetic induction strength makes Iron silicon an ideal choice for manufacturing high-power electronic devices.

Curve Comparison Chart

Advantage

-

01

High magnetic permeability

Iron silicon powder core has high magnetic permeability, which can effectively conduct magnetic fields, provide higher inductive inductance value and lower energy loss. This makes it have excellent performance in applications such as inductors and transformers.

-

02

Low core loss

Iron silicon powder cores exhibit lower core loss, which means that energy can be more effectively transmitted and converted in AC circuits. Low core loss helps to improve equipment efficiency and energy-saving performance.

-

03

Wide frequency range

The iron silicon powder core exhibits stability over a wide frequency range and can maintain low core losses. This makes it suitable for electronic devices and circuit applications of various frequencies.

-

04

Good temperature stability

The iron silicon powder core has good temperature stability and can maintain stable magnetic properties over a wide temperature range. This allows it to work reliably in environments with high temperatures or significant temperature changes.

-

05

High saturation magnetic

induction intensityIron silicon powder core has a high saturation magnetic induction intensity and can work under high magnetic field intensity. This makes it suitable for applications with high power and high magnetic field intensity.

-

06

Customizability

Iron silicon powder cores can be customized according to specific needs. By adjusting the size, shape, and ratio of powder particles, different magnetic properties and characteristics can be obtained to meet the requirements of different applications.

-

07

Reliability and stability

Iron silicon powder core has good stability and reliability, and can maintain its performance in long-term use. It has little impact on external magnetic field and temperature changes, and can provide stable working performance.

Applications

-

Industrial Power Supply

-

PV Inverter

-

Uninterruptible Power Supply

-

Household Appliance

-

APF

-

Energy Storage Power Station

-

Rail Transit