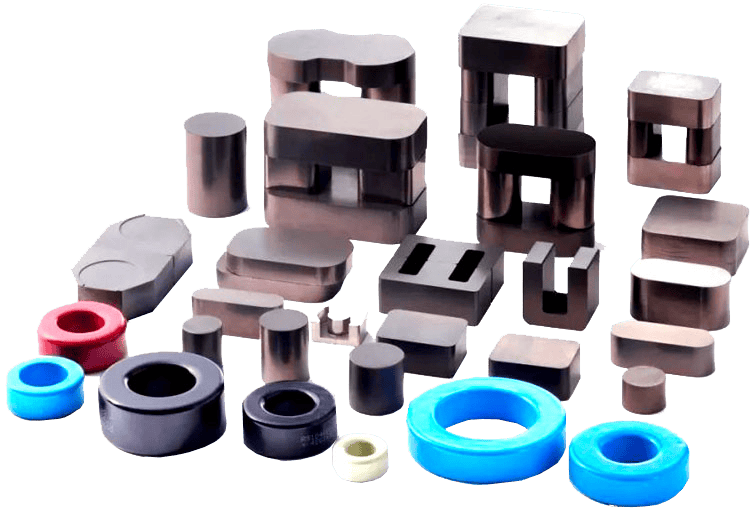

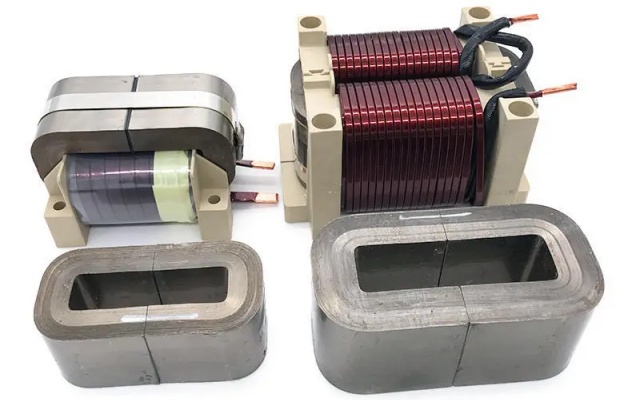

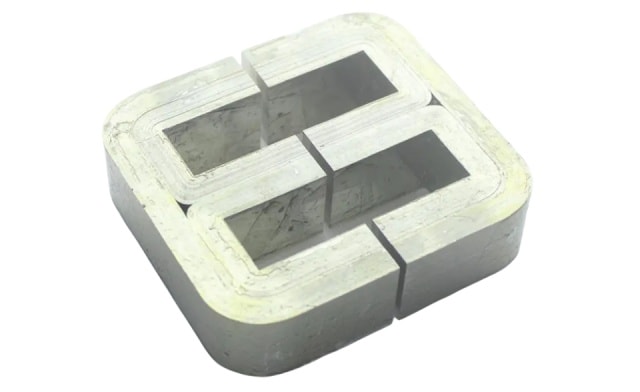

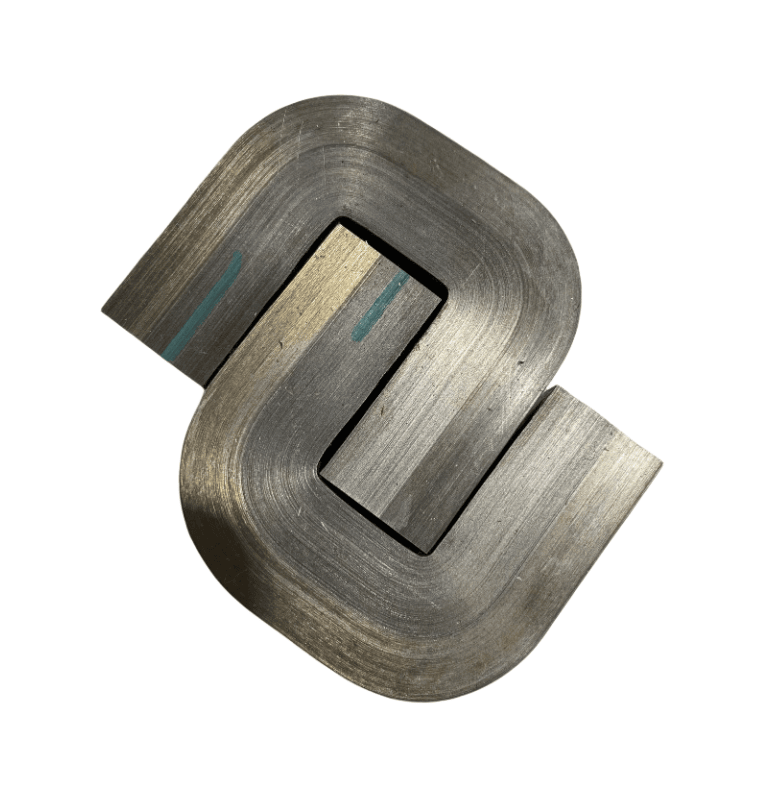

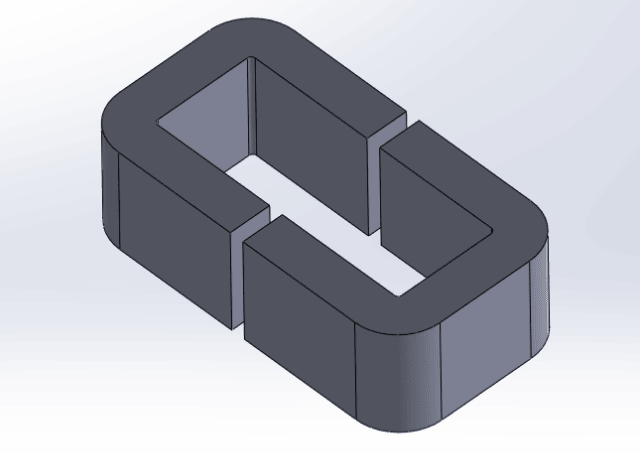

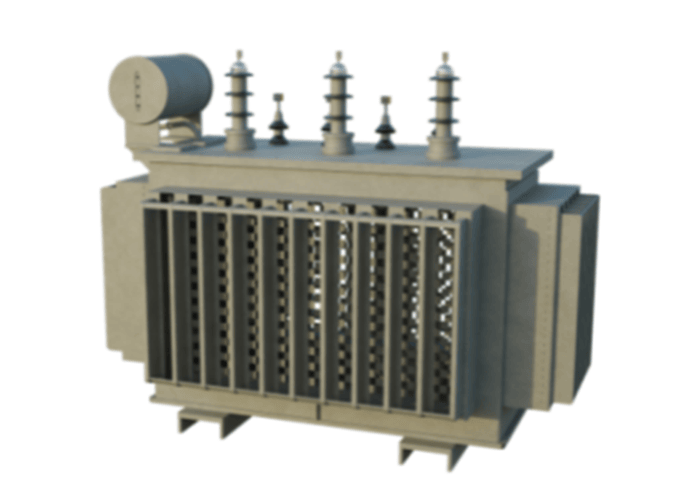

The versatility of amorphous cores makes them suitable for various fields such as transformers and inductors, sensors and detectors, power electronics, and high-frequency applications, achieving improved energy conversion efficiency, reduced energy loss, and providing stable signal processing and transmission capabilities.

Amorphous cores have gained significant attention across various industries due to their unique properties and versatility. Amorphous magnetic core materials are increasingly utilized in transformers and inductors, enhancing energy conversion efficiency while minimizing energy losses.

Amorphous core manufacturers

focus on producing high-quality materials that ensure stable signal processing and transmission, making them ideal for applications in power electronics and high-frequency devices. By leveraging the advantages of amorphous core materials, businesses can achieve superior performance in sensors and detectors, thus meeting the growing demands for efficient and reliable technology. With these advancements, amorphous cores are becoming essential components in modern electrical engineering solutions.

Welcome:Pourleroi