- Feature

- Performance

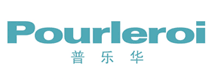

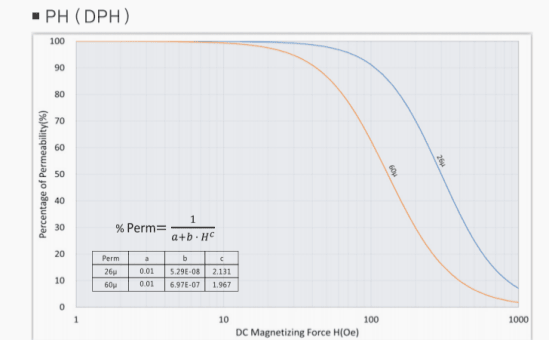

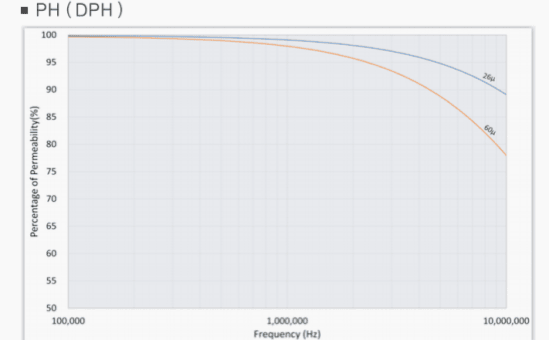

- Curve Comparison Chart

- Advantage

- Applications

- Video

Feature

Feature Description

High magnetic saturation;

Low loss powder core suitable for high efficiency power supply.

Performance

High saturation

High DC Sendust Cores of iron, silicon, and aluminum have a highly uniform composition distribution, where iron, silicon, and aluminum elements are uniformly dispersed in the powder. This high saturation helps to improve the performance of materials and the controllability of processing.

Excellent magnetic properties

High DC Sendust Core is a material with excellent magnetic properties. It exhibits the characteristics of high saturation magnetic induction intensity, low hysteresis, and low magnetic permeability, and is suitable for various magnetic applications, such as motors, transformers, and induction devices.

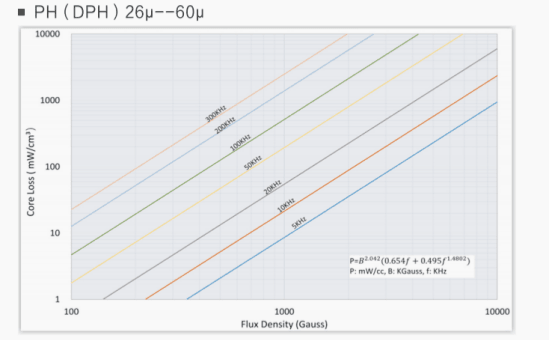

Good temperature stability

High DC Sendust Cores have good high-temperature stability and can maintain its magnetic and mechanical properties in high-temperature environments. This makes it suitable for high-temperature applications, such as automotive engines, aerospace fields, and energy conversion equipment.

Adjustable

The composition of high dc sendust core be adjusted by adjusting the raw material ratio and processing parameters to meet specific application requirements. This adjustability allows the material to possess different magnetic and mechanical properties as needed.

Good processing performance

High DC Sendust Cores have excellent processing performance and can be used to prepare various shapes and sizes of parts through processes such as pressing, sintering, and heat treatment. In addition, it can also be composite processed with other materials to obtain more functionality and performance.

Curve Comparison Chart

Advantage

-

01

High magnetic saturation

High DC Sendust Cores havehigh magnetic saturation, which means it can achieve high magnetic induction strength at lower magnetic field strengths. This makes it more efficient and efficient in magnetic applications.

-

02

Low hysteresis loss

Hysteresis loss refers to the energy loss generated during repeated changes in the magnetic field. High DC Sendust Coreshavethe characteristic of low hysteresis loss, which can reduce energy loss and improve energy efficiency.

-

03

Excellent magnetic permeability

High DC Sendust Cores havelower magnetic permeability, that is, lower conductivity to magnetic fields. This makes it demonstrate good performance in applications such as electromagnetic shielding and magnetic environment isolation.

-

04

Good temperature stability

High DC Sendust Coresexhibitgood thermal stability in high-temperature environments. It can maintain relatively stable magnetic and mechanical properties, and is not prone to demagnetization or structural changes, making it suitable for high-temperature applications.

-

05

Easy to process

High DC Sendust Cores havegood processing performance and can be prepared into various shapes and sizes of parts through various processing methods (such as pressing, sintering, heat treatment, etc.). This makes it have broad application prospects in the manufacturing field.

-

06

Adjustable

The composition of high DC sendust corescan be controlled by adjusting the raw material ratio and processing parameters. This adjustability allows materials to be customized according to specific application needs, meeting the requirements of different occasions.

-

07

Excellent magnetic properties

High DC Sendust Cores have excellent magnetic properties, including high saturation magnetic induction strength, low hysteresis, and low magnetic permeability. These characteristics make it widely used in fields such as electric motors, generators, transformers and induction devices.

Applications

-

New energy vehicles

-

PV Inverter

-

Uninterruptible Power Supply

-

Household Appliance

-

APF

-

Energy Storage Power Station

-

Air conditioner