- Feature

- Performance

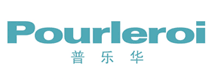

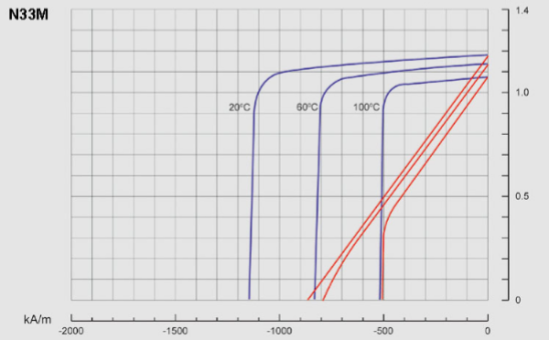

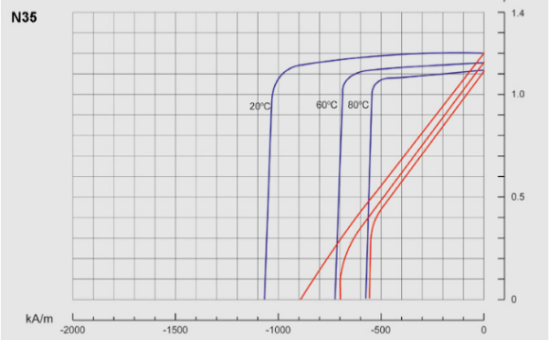

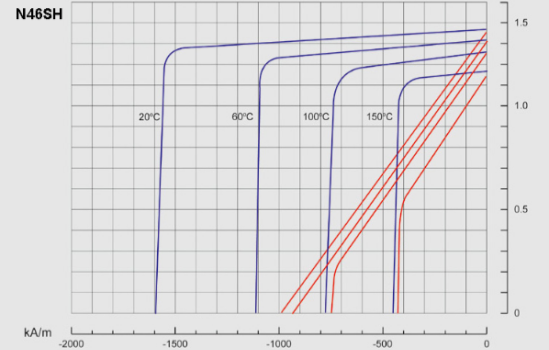

- Curve Comparison Chart

- Advantage

- Applications

- Video

Feature

Feature Description

High Magnetic Strength,

High Energy Density,

Excellent Magnetic Stability.

Parameters

| Parameters | ||||||||

|---|---|---|---|---|---|---|---|---|

| Material | Grade | Br | Hcb | Hcj | (BH)max | Temperture Coefficient | Tw | |

| mT(kGs) | kA/m(kOe) | kA/m(kOe) | kJ/m3(MGOe) | ∣ αBr ∣ %/ ℃ | ∣ βHcj ∣ %/ ℃ | ℃ | ||

| N | N35 | 1180-1230 (11.8-12.3) | ≥876 (≥11) | ≥955 (≥12) | 263-287 (33-36) | 0.10-0.124 | 0.65-0.80 | 80 |

| N38 | 1230-1260 (12.3-12.6) | ≥899 (≥11.3) | ≥955 (≥12) | 287-310 (36-39) | 0.10-0.124 | 0.65-0.80 | 80 | |

| N40 | 1260-1290 (12.6-12.9) | ≥912 (≥11.5) | ≥955 (≥12) | 302-326 (38-41) | 0.10-0.124 | 0.65-0.80 | 80 | |

| N42 | 1290-1330 (12.9-13.3) | ≥923 (≥11.6) | ≥955 (≥12) | 318-342 (40-43) | 0.10-0.124 | 0.65-0.80 | 80 | |

| N45 | 1330-1370 (13.3-13.7) | ≥931 (≥11.7) | ≥955 (≥12) | 342-366 (43-46) | 0.10-0.124 | 0.65-0.80 | 80 | |

| N48 | 1370-1400 (13.7-14.0) | ≥939 (≥11.8) | ≥955 (≥12) | 366-390 (46-49) | 0.10-0.124 | 0.65-0.80 | 80 | |

| N50 | 1390-1430 (13.9-14.3) | ≥947 (≥11.9) | ≥955 (≥12) | 374-406 (47-51) | 0.10-0.124 | 0.65-0.80 | 80 | |

| N52 | 1420-1460 (14.2-14.6) | ≥947 (≥11.9) | ≥955 (≥12) | 374-406 (47-51) | 0.10-0.124 | 0.65-0.80 | 80 | |

| N54 | 1450-1490 (14.5-14.9) | ≥912 (≥11.5) | ≥955 (≥12) | 406-438 (51-55) | 0.10-0.124 | 0.65-0.80 | 80 | |

| N56 | 1480-1520 (14.6-15.2) | ≥860 (≥10.8) | ≥876 (≥11) | 422-454 (52-57) | 0.10-0.124 | 0.65-0.80 | 70 | |

| M | 35M | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1114 (≥14) | 263-287 (33-36) | 0.10-0.124 | 0.60-0.75 | 100 |

| 35M | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1114 (≥14) | 263-287 (33-36) | 0.10-0.124 | 0.60-0.75 | 100 | |

| 40M | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1114 (≥14) | 302-326 (38-41) | 0.10-0.124 | 0.60-0.75 | 100 | |

| 42M | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1114 (≥14) | 318-342 (40-43) | 0.10-0.124 | 0.60-0.75 | 100 | |

| 45M | 1330-1370 (13.3-13.7) | ≥1002 (≥12.6) | ≥1114 (≥14) | 342-366 (43-46) | 0.10-0.124 | 0.60-0.75 | 100 | |

| 48M | 1370-1400 (13.7-14.0) | ≥1027 (≥12.9) | ≥1114 (≥14) | 366-390 (46-49) | 0.10-0.124 | 0.60-0.75 | 100 | |

| 50M | 1390-1430 (13.9-14.3) | ≥1035 (≥13.0) | ≥1114 (≥14) | 374-406 (47-51) | 0.10-0.124 | 0.60-0.75 | 100 | |

| 52M | 1420-1460 (14.2-14.6) | ≥995 (≥12.5) | ≥1114 (≥14) | 390-414 (49-52) | 0.10-0.124 | 0.60-0.75 | 100 | |

| 54M | 1450-1490 (14.5-14.9) | ≥995 (≥12.5) | ≥1114 (≥13) | 406-438 (51-55) | 0.10-0.124 | 0.60-0.75 | 90 | |

| H | 30H | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥1353 (≥17) | 223-247 (28-31) | 0.09-0.120 | 0.55-0.70 | 120 |

| 33H | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥1353 (≥17) | 247-271 (31-34) | 0.09-0.120 | 0.55-0.70 | 120 | |

| 35H | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1353 (≥17) | 263-287 (33-36) | 0.09-0.120 | 0.55-0.70 | 120 | |

| 38H | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1353 (≥17) | 287-310 (36-39) | 0.09-0.120 | 0.55-0.70 | 120 | |

| 40H | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1353 (≥17) | 302-326 (38-41) | 0.09-0.120 | 0.55-0.70 | 120 | |

| 42H | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1353 (≥17) | 318-342 (40-43) | 0.09-0.120 | 0.55-0.70 | 120 | |

| 45H | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥1353 (≥17) | 342-366 (43-46) | 0.09-0.120 | 0.55-0.70 | 120 | |

| 48H | 1370-1400 (13.7-14.0) | ≥1035 (≥13.0) | ≥1353 (≥17) | 366-390 (46-49) | 0.09-0.120 | 0.55-0.70 | 120 | |

| 48H | 1370-1400 (13.7-14.0) | ≥1035 (≥13.0) | ≥1353 (≥17) | 366-390 (46-49) | 0.09-0.120 | 0.55-0.70 | 120 | |

| 52H | 1420-1460 (14.2-14.6) | ≥1074 (≥13.5) | ≥1353 (≥17) | 390-417 (49-52) | 0.09-0.120 | 0.55-0.70 | 120 | |

| 52H | 1420-1460 (14.2-14.6) | ≥1074 (≥13.5) | ≥1353 (≥17) | 390-417 (49-52) | 0.09-0.120 | 0.55-0.70 | 120 | |

| SH | 30SH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥1592 (≥20) | 223-247 (28-31) | 0.09-0.120 | 0.50-0.65 | 150 |

| 33SH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥1592 (≥20) | 247-271 (31-34) | 0.09-0.120 | 0.50-0.65 | 150 | |

| 35SH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1592 (≥20) | 263-287 (33-36) | 0.09-0.120 | 0.50-0.65 | 150 | |

| 38SH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1592 (≥20) | 287-310 (36-39) | 0.09-0.120 | 0.50-0.65 | 150 | |

| 40SH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1592 (≥20) | 302-326 (38-41) | 0.09-0.120 | 0.50-0.65 | 150 | |

| 42SH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥1592 (≥20) | 318-342 (40-43) | 0.09-0.120 | 0.50-0.65 | 150 | |

| 45SH | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥1592 (≥20) | 342-366 (43-46) | 0.09-0.120 | 0.50-0.65 | 150 | |

| 48SH | 1370-1400 (13.7-14.0) | ≥1035 (≥13.0) | ≥1592 (≥20) | 366-390 (46-49) | 0.09-0.120 | 0.50-0.65 | 150 | |

| 50SH | 1390-1430 (13.9-14.3) | ≥1058 (≥13.3) | ≥1592 (≥20) | 374-406 (47-51) | 0.09-0.120 | 0.50-0.65 | 150 | |

| 52SH | 1420-1460 (14.2-14.6) | ≥1074 (≥13.5) | ≥1512 (≥19) | 390-414 (49-52) | 0.09-0.120 | 0.50-0.65 | 140 | |

| UH | 28UH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥1990 (≥25) | 207-231 (26-29) | 0.09-0.110 | 0.50-0.60 | 180 |

| 30UH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥1990 (≥25) | 223-247 (28-31) | 0.09-0.110 | 0.50-0.60 | 180 | |

| 33UH | 1140-1180 (11.4-11.8) | ≥827 (≥10.4) | ≥1990 (≥25) | 247-271 (31-34) | 0.09-0.110 | 0.50-0.60 | 180 | |

| 35UH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥1990 (≥25) | 263-287 (33-36) | 0.09-0.110 | 0.50-0.60 | 180 | |

| 38UH | 1230-1260 (12.3-12.6) | ≥923 (≥11.6) | ≥1990 (≥25) | 287-310 (36-39) | 0.09-0.110 | 0.50-0.60 | 180 | |

| 40UH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1990 (≥25) | 302-326 (38-41) | 0.09-0.110 | 0.50-0.60 | 180 | |

| 40UH | 1260-1290 (12.6-12.9) | ≥947 (≥11.9) | ≥1990 (≥25) | 302-326 (38-41) | 0.09-0.110 | 0.50-0.60 | 180 | |

| 45UH | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥1990 (≥25) | 342-366 (43-46) | 0.09-0.110 | 0.50-0.60 | 180 | |

| 48UH | 1360-1400 (13.6-14.0) | ≥1035 (≥13.0) | ≥1910 (≥24) | 358-390 (45-49) | 0.09-0.110 | 0.50-0.60 | 170 | |

| EH | 28EH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥2388 (≥30) | 207-231 (26-29) | 0.09-0.110 | 0.45-0.55 | 200 |

| 30EH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥2388 (≥30) | 223-247 (28-31) | 0.09-0.110 | 0.45-0.55 | 200 | |

| 33EH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2388 (≥30) | 247-271 (31-34) | 0.09-0.110 | 0.45-0.55 | 200 | |

| 35EH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥2388 (≥30) | 263-287 (33-36) | 0.09-0.110 | 0.45-0.55 | 200 | |

| 35EH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥2388 (≥30) | 263-287 (33-36) | 0.09-0.110 | 0.45-0.55 | 200 | |

| 35EH | 1180-1230 (11.8-12.3) | ≥899 (≥11.3) | ≥2388 (≥30) | 263-287 (33-36) | 0.09-0.110 | 0.45-0.55 | 200 | |

| 42EH | 1290-1330 (12.9-13.3) | ≥971 (≥12.2) | ≥2388 (≥30) | 318-342 (40-43) | 0.09-0.110 | 0.45-0.55 | 200 | |

| 45EH | 1330-1370 (13.3-13.7) | ≥1003 (≥12.6) | ≥2308 (≥29) | 342-366 (43-46) | 0.09-0.110 | 0.45-0.55 | 190 | |

| TH | 28TH | 1040-1090 (10.4-10.9) | ≥780 (≥9.8) | ≥2786 (≥35) | 207-231 (26-29) | 0.09-0.110 | 0.40-0.50 | 230 |

| 30TH | 1080-1140 (10.8-11.4) | ≥827 (≥10.4) | ≥2786 (≥35) | 223-247 (28-31) | 0.09-0.110 | 0.40-0.50 | 230 | |

| 33TH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2786 (≥35) | 247-271 (31-34) | 0.09-0.110 | 0.40-0.50 | 230 | |

| 33TH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2786 (≥35) | 247-271 (31-34) | 0.09-0.110 | 0.40-0.50 | 230 | |

| 33TH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2786 (≥35) | 247-271 (31-34) | 0.09-0.110 | 0.40-0.50 | 230 | |

| 33TH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2786 (≥35) | 247-271 (31-34) | 0.09-0.110 | 0.40-0.50 | 230 | |

| 33TH | 1140-1180 (11.4-11.8) | ≥860 (≥10.8) | ≥2786 (≥35) | 247-271 (31-34) | 0.09-0.110 | 0.40-0.50 | 230 | |

Curve Comparison Chart

Advantage

-

01

Exceptional Magnetic Properties

NdFeB magnets possess the highest magnetic strength among commercially available magnets. They offer significantly stronger magnetic fields compared to other types of magnets, allowing for superior performance in terms of attraction, holding force, and magnetic field generation.

-

02

High Energy Density

NdFeB magnets have a high energy density, meaning they can store a large amount of magnetic energy in a relatively small volume. This makes them compact and ideal for applications where space is limited, such as in 4miniaturized electronic devices or small motors.

-

03

Wide Range of Operating Temperatures

NdFeB magnets can operate effectively over a broad temperature range, depending on their grade. They exhibit good magnetic stability and can maintain their magnetic properties at high temperatures, making them suitable for use in various environments and applications.

-

04

Strong Resistance to Demagnetization

NdFeB magnets have excellent resistance to demagnetization, allowing them to maintain their magnetic strength over time. This makes them reliable and durable for long-term use.

Applications

-

Loudspeakers and Audio Devices

-

Computer Hard Drives

-

Sensors and Actuators Magnetic Separators

-

Electric Motors

-

Generators