Welcome:Pourleroi

In the realm of modern electronics and power applications, the selection of appropriate electromagnetic components plays a pivotal role in ensuring efficiency, reliability, and performance. Among these components, iron powder cores and ferrite cores stand out as two crucial materials used in the design of inductors, transformers, and other electromagnetic devices. Each material offers distinct physical and magnetic properties that can significantly influence the functionality and efficiency of electronic circuits and power systems.

This article aims to delve into a comprehensive comparison between iron powder cores and ferrite cores, shedding light on their unique attributes, advantages, and limitations. By understanding the differences in their basic composition, manufacturing processes, and performance across various applications, designers and engineers can make informed decisions tailored to their specific project needs. The comparison will not only highlight the suitability of each core type for different frequency ranges and power requirements but also consider factors such as cost, availability, and design complexity. Through this exploration, we seek to equip professionals in the field with the knowledge to optimize their designs for enhanced performance and efficiency, navigating the intricate choices that modern electromagnetic applications demand.

Iron powder cores are a pivotal component in the realm of electromagnetic design, offering a blend of versatility and performance that is tailored for a broad spectrum of applications. Comprising finely ground iron particles insulated and compressed to form a core, these components are distinguished by their ability to mitigate eddy current losses at high frequencies. This insulation between individual particles allows for the core to operate efficiently by reducing the undesirable effects of eddy currents, which can lead to energy dissipation in the form of heat.

The manufacturing process of iron powder cores involves mixing iron powder with an insulating binder, which is then pressed into desired shapes and sizes. This process allows for a high degree of customization, making iron powder cores adaptable to various applications ranging from power electronics to RF circuits.

One of the defining characteristics of iron powder cores is their excellent frequency response, maintaining effectiveness over a wide range of frequencies. This makes them particularly suitable for high-frequency applications where traditional ferrite cores might lose efficiency due to increased eddy current losses. Moreover, iron powder cores can handle high current levels, making them ideal for use in power conversion and energy storage applications.

One of the defining characteristics of iron powder cores is their excellent frequency response, maintaining effectiveness over a wide range of frequencies. This makes them particularly suitable for high-frequency applications where traditional ferrite cores might lose efficiency due to increased eddy current losses. Moreover, iron powder cores can handle high current levels, making them ideal for use in power conversion and energy storage applications.

However, the performance of iron powder cores can be influenced by the core material's permeability and the core size, which dictate their applicability in different circuit designs. They are commonly used in inductors, transformers, and filters where efficient energy storage and minimal core losses are crucial.

In summary, iron powder cores offer a reliable and efficient solution for managing electromagnetic interactions in a variety of applications. Their ability to reduce eddy current losses while providing a high level of customization in terms of shape and size makes them a favored choice among engineers and designers in the field of electronic and electrical engineering.

Overview of Ferrite Cores

Ferrite cores represent a cornerstone in the construction of inductors, transformers, and other electromagnetic components, especially in applications requiring efficient performance at lower frequencies. Composed of a mix of iron oxide combined with various metallic elements such as manganese and zinc, these ceramic-like materials are celebrated for their high magnetic permeability and low electrical conductivity. This unique combination allows ferrite cores to effectively contain magnetic fields while minimizing eddy current losses, which is particularly advantageous in low-frequency applications.

The production process of ferrite cores involves sintering, a method where powdered materials are formed and then heated without melting to create a solid form. This process yields a material that is both electrically insulating and magnetically conductive, a duality that is critical for reducing losses in electromagnetic devices. The inherent properties of ferrite cores make them highly effective in suppressing interference in electronic signals and in the efficient transfer of energy in power supply circuits.

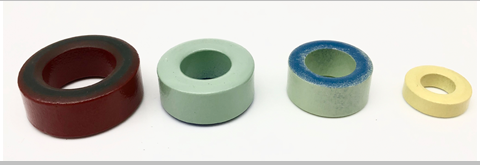

Ferrite cores come in various shapes and sizes, including toroids, rods, and E-cores, each suited to different types of applications. Their high efficiency at lower frequencies makes them particularly suitable for use in the cores of transformers and inductors in consumer electronics, telecommunications, and power electronics. Additionally, the low power loss characteristics of ferrite materials make them ideal for applications where energy efficiency is a priority.

Despite their lower efficiency at higher frequencies compared to alternatives like iron powder cores, ferrite cores remain a popular choice due to their effectiveness in preventing signal loss and their capability to operate under a wide temperature range. This makes ferrite cores an indispensable component in the design of electronic circuits, offering a balance between performance and cost-effectiveness in applications where low-frequency operation is paramount.

Comparison Between Iron Powder Cores and Ferrite Cores

The comparison between iron powder cores and ferrite cores is essential for designers and engineers looking to optimize their electromagnetic components for specific applications. Each core type brings unique properties and advantages to the table, influencing their suitability across various applications.

Iron powder cores are known for their high saturation levels and are typically used in applications where high current handling is required. Their structure, composed of insulated iron particles, minimizes eddy current losses, making them highly efficient in high-frequency applications. However, their magnetic permeability is generally lower compared to ferrite cores, which can be a limiting factor in applications requiring high inductance values.

Ferrite cores, on the other hand, boast high magnetic permeability, allowing them to store more energy and thus, are often used in applications demanding high inductance at lower frequencies. They exhibit lower saturation levels than iron powder cores, making them less ideal for handling high current applications. Ferrite cores also tend to have better temperature stability, which is crucial for applications subjected to varying environmental conditions.

Iron powder cores excel in high-frequency applications due to their low eddy current losses. This characteristic makes them suitable for use in switch-mode power supplies, high-frequency transformers, and noise suppression components. Their performance remains relatively stable across a broad frequency range, from the low kHz to the MHz spectrum.

Ferrite cores are predominantly used in low to medium frequency ranges, typically up to a few MHz. Their high magnetic permeability allows for efficient performance in applications such as power transformers, inductors, and electromagnetic interference (EMI) filters. However, their effectiveness decreases at higher frequencies due to increased losses.

In power electronics, iron powder cores are preferred for their ability to handle high currents and efficiency in high-frequency power conversion applications. Their robustness and versatility make them suitable for inductors and transformers in switch-mode power supplies.

Ferrite cores find extensive use in applications requiring efficient magnetic performance at lower frequencies. They are ideal for use in broadband transformers, common mode chokes, and applications where minimizing EMI is crucial. Their high permeability and low core losses at lower frequencies make them the go-to choice for many power transformer and inductor applications.

Cost and availability play significant roles in choosing between iron powder and ferrite cores. Iron powder cores can be more expensive due to the cost of raw materials and the manufacturing process. However, their durability and efficiency in high-frequency applications often justify the investment.

Ferrite cores are generally less expensive and widely available, making them a cost-effective solution for a variety of applications, especially in bulk or consumer-grade products. Their lower cost does not compromise their utility in suitable applications, offering an excellent balance between performance and expenditure.

Choosing between iron powder cores and ferrite cores depends on several factors, including the required frequency range, current handling capability, temperature stability, and cost considerations. Iron powder cores are more suited for high-frequency, high-current applications, while ferrite cores excel in lower frequency applications where high inductance and minimal EMI are desired. Understanding the unique attributes and limitations of each core type is crucial for optimizing the performance and efficiency of electromagnetic components in any application.

By continuing to use the site you agree to our privacy policy Terms and Conditions.